State Key Laboratory of Transducer Technology Invented the Degradable "Silk Fibroin Bone Peg"

Date:31-08-2017 | 【Print】 【close】

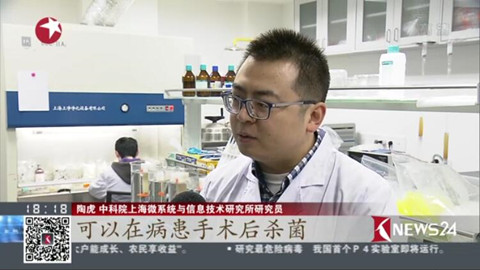

Recently, Tao Hu, Researcher of the State Key Laboratory of Transducer Technology, Shanghai Institute of Microsystem and Information Technology (SIMIT) and his team invented a new kind of degradable biomedical device with controllable degradation rate through the silk in the traditional textile industry. Shanghai TV News Comprehensive Channel Reporter Zhang Guoxia conducted an exclusive interview on this technology. The relevant results were published in the latest issue of "Advanced Materials" (Influence Factor 18.96), DOI: 10.1002 / adma.201605471, entitled "Soluble Optical Diffraction Sensing Technology Based on Functional Silk Fibroin".

In view of the trouble that the traditional medical instrument "Bone peg" with the fixation function is mostly made of titanium alloy or stainless steel at present, which requires a second operation to remove after rehabilitation, Tao Hu's team completed the biological material production process from cocoon to silk, then to silk fibroin solution, from which solid was extracted, and finally processed into bone peg using lathe for precision finishing. The biological materials not only have the degradable function that can be controlled precisely, but also have the effectiveness in drug encapsulation, micro-surgery, information hiding, food fresh keeping, drug storage and many other aspects.

Recently, the animal experimental stage of this technology has been completed, and further cooperation with biomedical enterprises has been made to carry out clinical research. It is expected to be commercialized and launched to the market within three to four years, with further formation of production, study and research integrated innovation and development.

In the interview, Tao Hu also did the math with the reporter. Currently, a silk quilt needs to use 5 kg of silk materials, with the selling price of more than 1,000 yuan; while a set of silk fibroin bone peg only needs less than 0.5 gram of cocoon, i.e., a silk quilt can be used to make two to three thousand sets of medical equipment, with the price of about 10,000 per set. Hence, once the technology takes shape and comes out, it is expected to transform the traditional low value-added industry into high-tech and high value-added bio-pharmaceutical industry.

| 附件下载: |