With the patented technology as the core, the Institute’s MEMS manufacturing technology has formed four sets of MEMS manufacturing process portfolios, and set up the only MEMS manufacturing technology platform in China integrating chip manufacturing and packaging. The multilayer three-dimensional micromechanical structure once forming technology invented is capable of etching out multilayer three-dimensional micromechanical structure at one time. The (100) silicon wafer along (100) orientation compensation technique for <100> convex corner undercutting in KOH anisotropic etching invented could make structurally controllable micromechanical structure along the (100) orientation

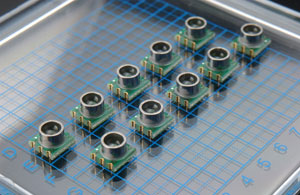

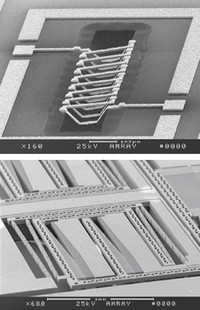

With the patented technology as the core, the Institute’s MEMS manufacturing technology has formed four sets of MEMS manufacturing process portfolios, and set up the only MEMS manufacturing technology platform in China integrating chip manufacturing and packaging. The multilayer three-dimensional micromechanical structure once forming technology invented is capable of etching out multilayer three-dimensional micromechanical structure at one time. The (100) silicon wafer along (100) orientation compensation technique for <100> convex corner undercutting in KOH anisotropic etching invented could make structurally controllable micromechanical structure along the (100) orientation  based on the (100) silicon wafer. The dry etching stored charge release and movable structure protection technology invented could effectively inhibit the Footing effect and improve the manufacture yield rate. The new Wafer-Level Packaging (WLP) method invented could increase the packaging efficiency of the devices including movable structures. Moreover, nine papers have been selected from of the Microsystem Institute, including China’s only invited lecture and three oral lectures, with both quantity and quality of papers top the national sister institutions. Meanwhile, the scientific research capacity is highly recognized by the peers internationally. With these technologies as the core, the Institute has achieved many research results including the vibration transducer, the biochemical trace detection sensor, and the infrared gas sensor, etc., with the packaging technologies in devices, modules and systems meeting the needs of various microsystem integrations, and providing chip customization and packaging services to users in aviation, electronics and corporate, etc.

based on the (100) silicon wafer. The dry etching stored charge release and movable structure protection technology invented could effectively inhibit the Footing effect and improve the manufacture yield rate. The new Wafer-Level Packaging (WLP) method invented could increase the packaging efficiency of the devices including movable structures. Moreover, nine papers have been selected from of the Microsystem Institute, including China’s only invited lecture and three oral lectures, with both quantity and quality of papers top the national sister institutions. Meanwhile, the scientific research capacity is highly recognized by the peers internationally. With these technologies as the core, the Institute has achieved many research results including the vibration transducer, the biochemical trace detection sensor, and the infrared gas sensor, etc., with the packaging technologies in devices, modules and systems meeting the needs of various microsystem integrations, and providing chip customization and packaging services to users in aviation, electronics and corporate, etc.